Your cart is currently empty!

Textiles: From Fibers to fabric and Fabric Manufacturing Techniques

•

Introduction

We discus here from Fibers to fabric and Fabric Manufacturing Techniques. Textiles are a necessary part of our daily lives; specially from the clothes to the furniture we use. But you should know how textile fabric made? This blog will help you through the fascinating journey of textiles — It start from fibers, yarn, and finally fabric using different manufacturing techniques such as knitting, weaving and nonwoven processes.

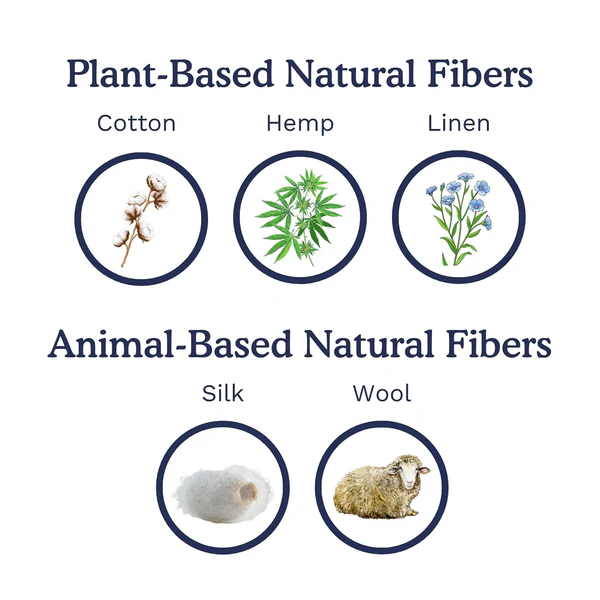

The Basics of Textile Materials

Fibers are thread-like structures that can be long, thin, and flexible. They can be classified into two main categories:

- Natural Fibers: These come from plants or animals. Examples include:

- Cotton

- Wool

- Silk

- Flax

- Synthetic Fibers: These are man-made fibers produced through chemical processes. For example.

- Polyester

- Nylon

- Acrylic

Man made fibers and natural fibers have different properties for end product.

From Fibers to Yarn: The Spinning Process

Once fibers are obtained, the next step is to turn them into yarn. This is done through spinning, where fibers are twisted together to form continuous threads. The quality of the yarn depends on the type of fibers used, the spinning method, and the amount of twist.

Types of Yarn

- Single Yarn: Made from a single strand of fibers twisted together.

- Ply Yarn: Created by twisting two or more single yarns together for strength and texture.

- Textured Yarn: Yarns modified to add bulk, stretch, or special effects.

- Filament Yarn: Composed of continuous long fibers, often synthetic, resulting in smooth and shiny yarns

Fabric Manufacturing Techniques

After yarn is made, it is converted into fabric. There are three main techniques:

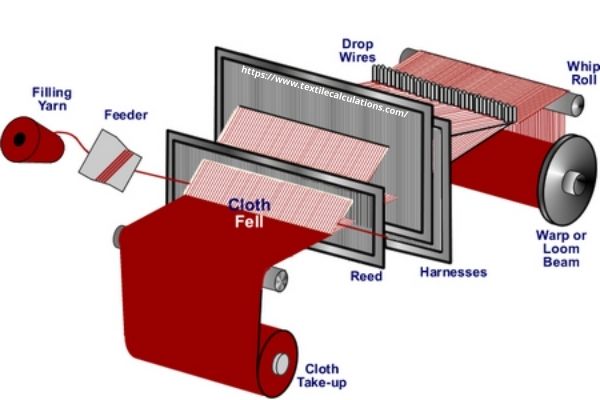

A. Weaving

- Process: Interlacing of yarns (warp and weft) is weaving

- Characteristics: Woven fabrics are strong, durable, and less stretchable.

- Common Uses: Denim, cotton shirts, home textile.

B. Knitting

There are three types of the fabric manufacturing process. They are weaving, knitting, and non-weaving. Knitted fabric produced by loop forming. Such type of fabric huge demand in the present world. For the manufacturing of knitted fabric, the process flow chart of knitting technology is given below.

- Process: it is interloping of yarn in which is created.

- Characteristics: Knitted fabrics are more flexible, stretchy, and comfortable as compare to weaving.

- Common Uses: T-shirts, bodies, uppers, sweaters, knitted caps, socks.

Process Flow Chart for Knitting

- Yarn in package form

↓

Place the yarn package in the creel

↓

Feeding the yarn

↓

Set the m/c as per design & GSM

↓

Knitting

↓

Withdraw the roll fabric and weighting

↓

Roll marking

↓

Inspection

↓

Numbering

C. Nonwoven

- Process: Bonding fibers together using heat, chemicals, and chemically.

- Characteristics: Usually lightweight, disposable and durable.

- Common Uses: Medical masks, wipes, filters.

Conclusion

The journey from fibers to yarn and then fabric created by using above technique. Each stage, from choosing the right fiber to selecting the fabric manufacturing method, plays a crucial role in determining the quality and functionality of the final textile product now days emerging technique by using it production and comfort increases.

Leave a Reply